DOSING FOR INDUSTRY

Dosing system for Industry

MAFA offers precise dosing systems adapted for industry.

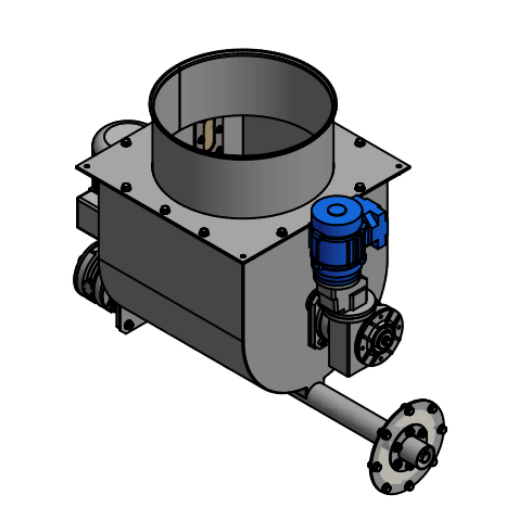

MAFA Auger Dispensers

MAFA Auger doser for accurate dosing of granules. The metering auger can be frequency controlled to achieve the desired accuracy. The auger doser is manufactured according to the customer’s specifications to achieve the best possible function in the plant.

The main components include a container, metering auger, electric motor with gear, agitator and possibly weighing equipment.

All MAFA electric motors are equipped with overheating protection.

Why choose MAFA Auger Dispensers?

- Accurate dosing of feed, fuel pellets or granules

- With frequency control for desired accuracy

- With agitator

- Engine with overheating protection

- Volume of container approx. 1 liter – 3000 liters

- Manufactured to customer specifications

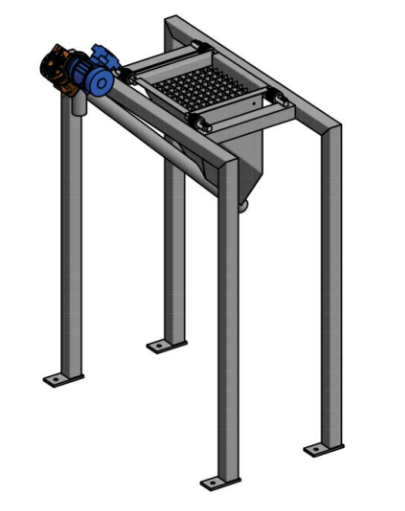

MAFA Dosers

MAFA Doser for accurate dosing of granules. The metering auger can be frequency controlled to achieve the desired accuracy. In order to achieve the best possible function in the plant, the dispenser is manufactured according to the customer’s specifications.

The MAFA Doser is made for use indoors in a dry and temperate space. The main components include the hopper, metering auger, electric motor with gear and possibly weighing equipment.

All MAFA electric motors are equipped with overheating protection.

Why choose MAFA Dosers?

- Accurate dosing for an indoor process

- With frequency control for desired accuracy

- Engine with overheating protection

- Manufactured to customer specifications

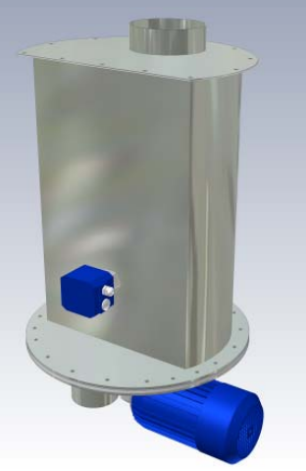

Rotofill

The MAFA Rotofill stainless steel doser is particularly suitable for dosing dry powdered materials. For a very even dispensing and precise dosing without reflowing. The dispenser is equipped with a frequency-controlled dispensing knife at the bottom and weight-controlled dosing. The capacity of the dispenser depends on the material and drive.

In order to achieve the best possible function in the plant, the dispenser is manufactured according to the customer’s specifications.

Why choose Rotofill?

- Accurate dosing of dry materials in powder form

- Smooth Dispensing and Precise Dosing

- Frequency-controlled output knife at the bottom

- Can be manufactured to customer specifications

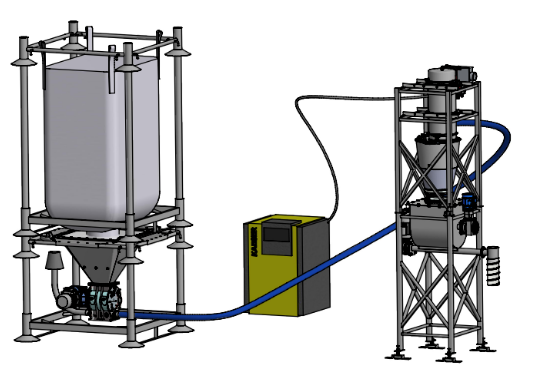

Starch dosing plant

MAFA develops complete facilities for dosing starch. We tailor your solution with components such as dosers and control systems for precise dosing, vacuum conveyor, big bag stand with cell lock, etc.

Feel free to contact us for more information.

Why choose our Starch Dosing Plant?

- Complete starch dosing plant

- Tailor-made solution

- With doser and control system for precise dosing

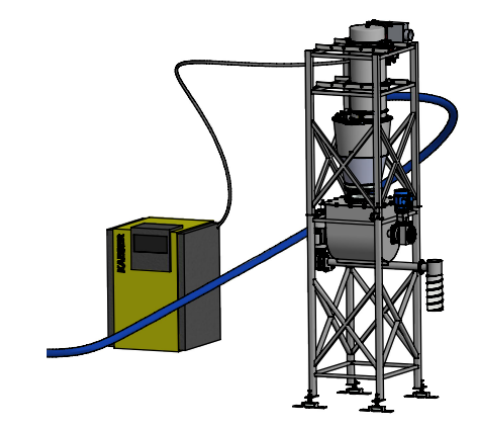

Dosing plant for fluidizers

MAFA develops complete systems for dosing fluidizers. We tailor your solution with components such as dosers, control systems for precise dosing and vacuum conveyors.

Feel free to contact us for more information.

Why choose our Fluidizer Dosing Plant?

- Complete fluidizer dosing plant

- Tailor-made solution

- With dosers, control system for precise dosing and vacuum transport

Fiber dosing system

Flexible fiber dosing system specially developed for dosing fiber, pigments and other additives in pellet or granular form. The system is ideal for asphalt plants, for example, and can handle batches up to 4 tons.

We tailor your system with our unique silos made of aluzinc, complete level monitoring with overfill protection, systems for weighing, mixers, transport solutions, motors and intermediate storage.

Our systems are developed for high reliability and optimal efficiency.

The MAFA fiber dosing system is available both as a stationary and mobile device and can.

Feel free to contact us for more information.

Why choose MAFA fibre dosing systems?

- Flexible dosing of additives in pellet or granular form

- Capable of handling batches up to 4 tons

- Constant fiber quality with minimal air mixing

- The system is tailored to the customer’s specifications, together with MAFA’s other products

- Suitable for asphalt plants, among other things