Accessories

Accessories

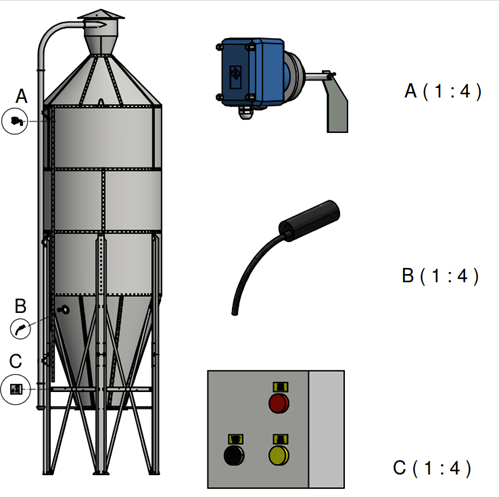

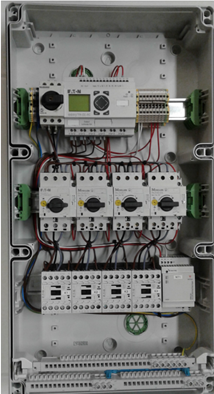

Level monitoring

Overfill protection & low level guard

MAFA paddle guards & capacitive sensors with a common connection point for level guards mounted in, for example, a silo.

The junction boxes are equipped with terminals for connection of supply voltage, level sensors and external warning lights for max and min level.

It is also possible to get 24VDC to connect, for example, a weighing instrument. Available in two versions, for use with one or two sensors.

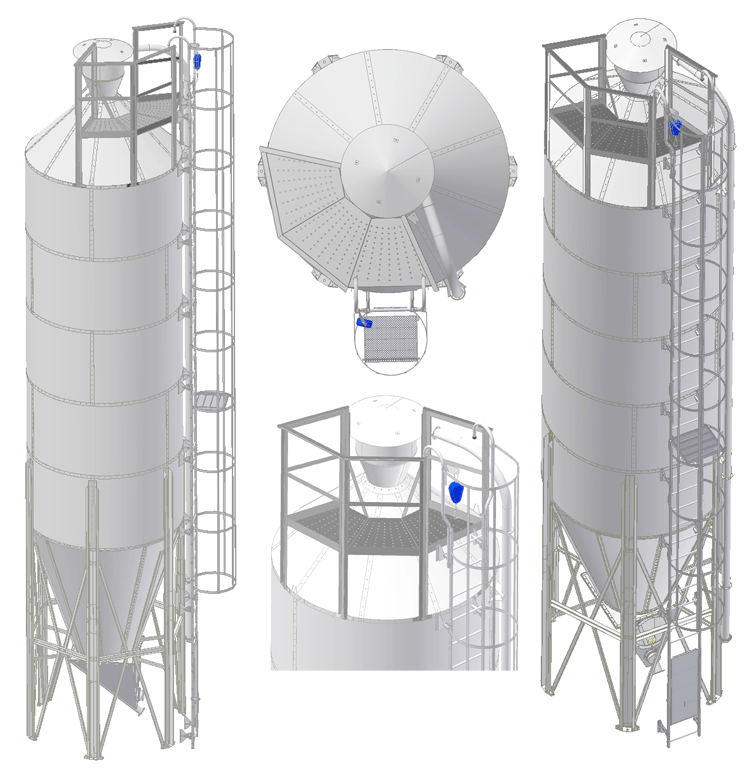

Silo weighing

With MAFA Silo weighing, you get control of delivered material and consumption in the best and most accurate way.

A set for silo weighing consists of load cells incl. pressure plate, junction box, attachment for silo foot and instrument for displaying the contents of the silo in kg.

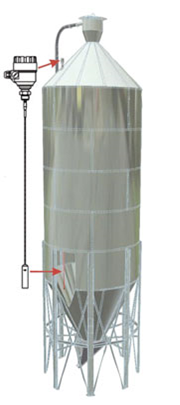

Guided microwave Level sensor

ATEX-classified according to EEx 1/2 d

MAFA Guided microwave Level sensor is excellent for solid materials such as feed and wood pellets and works according to the TDR (Time Domain Reflectometry) principle, which is well known from measuring cable interruptions.

The distance to the material is directly proportional to the pulse time. The TDR technology is independent of the material and the space above. The measured signal is converted to a 4 – 20 mA current and a HART signal for further processing. Micropulses are sent along a line at the speed of light. When the pulse reaches the material surface, it is reflected back to the level transmitter.

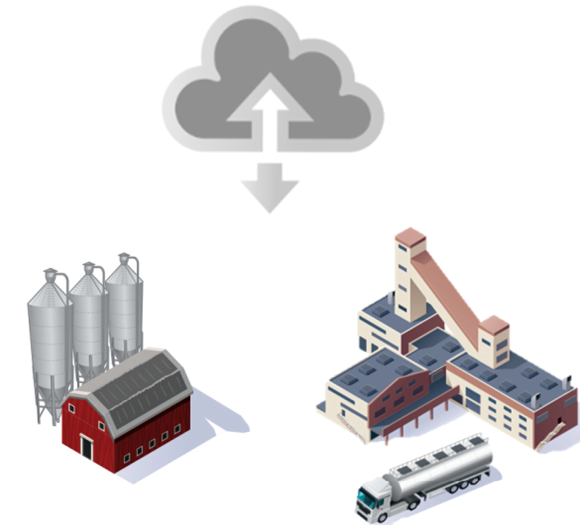

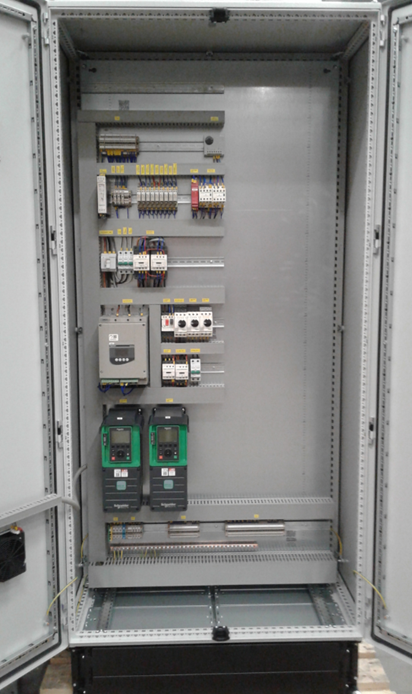

MAFA Connect

En komplett molnbaserad lösning för nivåkontroll i silo.

MAFA Connect sköter bevakningen av materialnivån i silon, och presenterar på ett enkelt sätt mätvädena i mobiltelefon eller dator.

MAFA Connect kan även anslutas till din leverantör av bulkvaran, det ger både dig och din leverantör ökad trygghet och fördelarna av välplanerade leveranser.

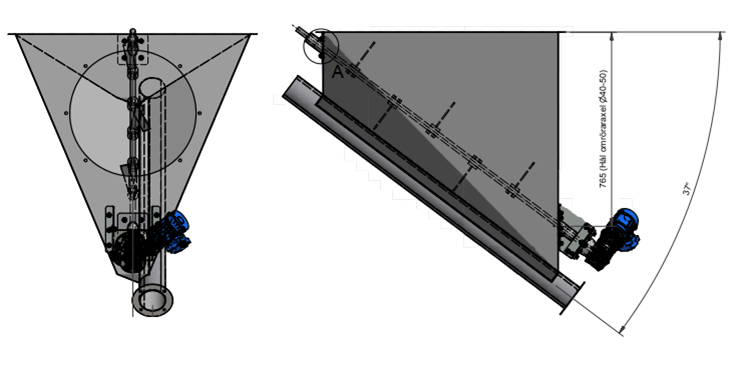

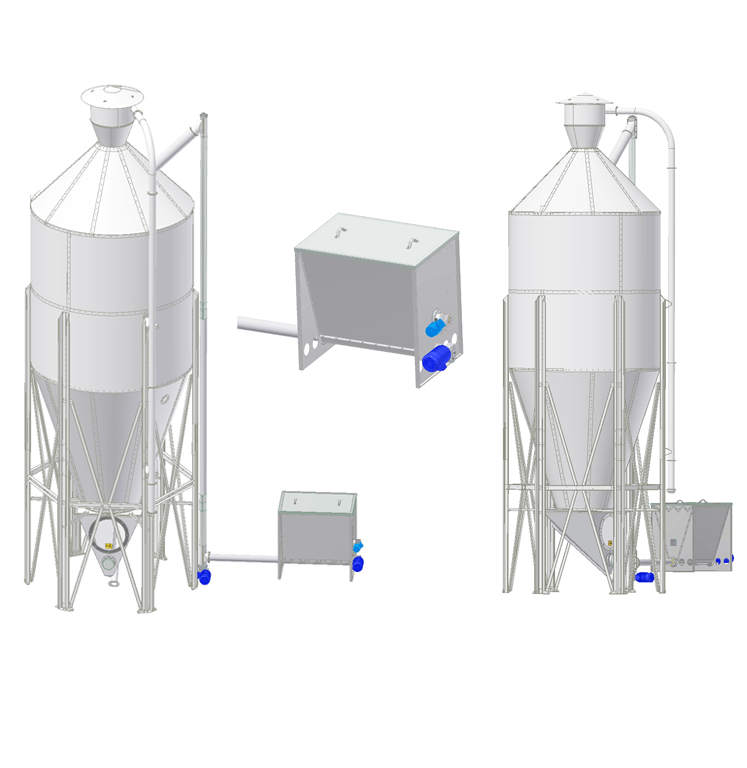

Silo filler

The silo filler is used when you want to fill material from small or Big bags into a silo. The system consists of a mineral dispenser connected to transport auger. In the Mineral Dispenser, a grille is mounted. It is used partly as protection against the rotating transport auger and partly it can be used to put sacks on when emptying (maximum weight 1000 kg).

The transport auger is mounted against the mineral dispenser and vertically up along the silo. From the outlet, material is released through the silo roof.

Start pipe & transport pipe

Our range includes filling and transport pipes, bends, brackets and cyclones in a variety of sizes.

• Start pipes are available in lengths from 0.17 m to 1 m.

• Transport pipes are available in lengths from 0.5 m to 3 m.

• Bends at 45 ° resp. 90 ° bend.

• 90 ° bend is also available with a long radius.

• Wall bracket is available for horizontal resp. vertical mounting.

• Cyclones are manufactured in several sizes.

• The wall thickness of the pipes is 1.5 mm and bends at 2.0 resp. 3.6 mm.

• All pipes are hot-dip galvanized.

The picture shows from below: filling lock, start pipe with horizontal wall bracket, rubber gasket, transport pipe with vertical wall bracket, 90 ° long radius bend, 45 ° bend, 90 ° bend, pipe flange for wall mounting and cyclone.

Technical data:

extended diameter

wall thickness

radius

construction dimensions

Tubes

101,6 mm

1,5 mm

Bend short radius

101,6 mm

3,6 mm

237,5 mm

290 mm

Bend long radius

101,6 mm

2,0 mm

575 mm

920 mm

Flange

145 mm