MAFA's bioenergy system solutions fit into any environment

If you invest in a MAFA biofuel plant, you get the opportunity to choose a plant that is integrated into the property. The silo is an important part of the system and it is especially important in public environments and rental properties that the silo is chosen with great care so that it is best adapted and blends into the existing surroundings.

Should the silo be placed outdoors or indoors? Should it be freestanding or built-in? Is the local environment particularly sensitive in any respect? Is it an advantage if the silo is designed or that it can be painted or built in?

There are many questions and the plant must also function regardless of climate and temperature fluctuations. It should require little supervision and should have a built-in warning system that prevents unwanted downtime.

A MAFA silo is equipped with a sensor that warns of the risk of overfilling and a cyclone with natural ventilation that makes the pellet storage condensation-free. The rest of the pellet handling up to the burner is ensured with an electronic control that monitors that everything is done correctly.

The entire facility only needs supervision from time to time, to ensure that everything works as it should. All silos are tested and proven and we recommend that the silo is ordered fully assembled from MAFA.

Mafa has a wide range of silos that can be used to store pellets and other bioenergy.

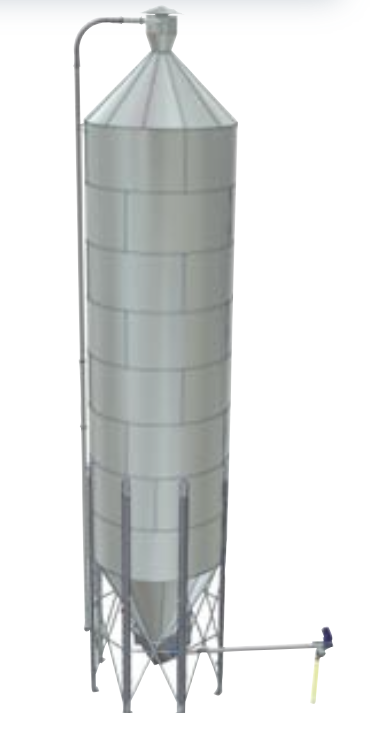

MAFA round Uniksilo:

Where possible, a round silo should be used. They are stable, reliable, easy to fill and empty. They have natural ventilation as standard and can be upholstered at the bottom and/or painted. There are many sizes and models from 6 m3 to 189 m3. Builds on height and therefore needs a small area of land. Round silos are only available for outdoor placement and they require a building permit.

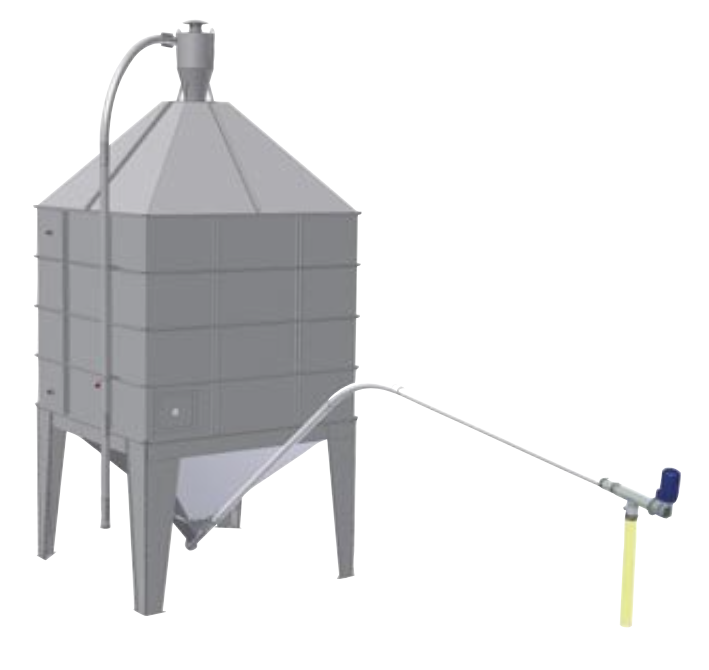

MAFA module silo:

Available for both indoor and outdoor use. Slightly lower than the Unik silo. Can be clad at the bottom and/or painted. Available in many models with different widths and heights. Builds on height and requires a building permit when placed outdoors.

MAFA Succé silo:

Available for both indoor and outdoor placement. They are easy to assemble, build in, cover and can be painted. They do not build on height and there is no need for a building permit indoors. Available in many sizes and models from 5.0 to 30.3 m3. Very useful for installations up to 400 kW.

MAFA has pellet silos for all heating needs

MAFA offers a wide range of silos. They are tested and proven and can be ordered both unassembled and assembled. A factory-fitted silo comes with a crane truck and is put on a cast plate.

MAFA Succé BS – with gable emptying

The BS silo is available in lengths of 2 m and 3 m, in heights between 2.1 and 3.6 m. Width 1.88 m. (5.0 m3 – 15.7 m3). Made of maintenance-free aluzinc sheet complete with filling pipe incl. blower chute, vent, manhole incl. sight glass, shut-off damper and center pipe. Delivered unassembled or factory-assembled.

MAFA Succulent BSM – with center socket

The BSM silo is available in lengths of 3 m, 4 m, 5 m and 6 m, in heights between 2.1 m and 3.6 m. Width 1.88 m (7.6 m3 – 30.3 m3). Made of maintenance-free aluzinc sheet complete with filling tube, venting through dust filter, manhole, sight glass, shut-off damper over screw conveyor and leg stand. Incl. center socket, 400 mm inspection door, right/left screw, worm gear motor 12 rpm, drive pins, end bearings and capacitive sensor. Delivered unassembled or factory-assembled.

MAFA UNIK Small UNS – round silo with a diameter of 1.88 m

The UNS silo is available in heights between 5.33 m to 7.25 m (6.3 m – 11.5 m). Made of maintenance-free aluzinc sheet, complete with filling pipe with long-radius bend, cyclone filling with deaeration, special cone for separation-free emptying and sight glass. Excl. damper and screw box. Delivered factory-assembled.

MAFA UNIK UN – round silo with a diameter of 2.34 m

The UN silo is available in heights between 6.45 m and 12.45 m (12 m – 37.8 m3). Made of maintenance-free aluzinc sheet, complete with filling pipe with long-radius bend, cyclone filling with deaeration, special cone for separation-free emptying and sight glass. Excl. damper and screw box. Delivered factory-assembled.

MAFA BIB – round industrial silo with a diameter of 3.10 m

The BIB silo is available in heights between 6.95 m to 15.35 m (21.1 m – 85.2 m). Made of maintenance-free aluzinc sheet, complete with filling pipe with long-radius bend, cyclone filling with venting, cone with smooth inside that allows the silo to empty well. Equipped with a special bolt with a smooth skull and sight glass. Excl. damper and screw box. Delivered factory-assembled.

MAFA XB – Round large silo with a diameter of 4.68 m

The XB silo is available in heights between 9.5 m to 15.5 m (86.1 m3 – 189.3 m3). Made of maintenance-free aluzinc sheet, complete with filling pipe with long radius bend, cyclone filling with venting, cone with smooth inside that allows the silo to empty well. Excl. damper and screw box, wall and roof ladder and top hatch. Delivered unassembled or assembled on site.

MAFA Outdoor modular silo – with 45 degree cone.

The outdoor modular silo is available in the dimensions 1.5×1.5 m, 2.05×2.05 m, 2.55×2.55 m and 3.0×3.0 m. (1.7 m3 – 50.0 m3). Made of galvanized steel plate. The silo is delivered incl. dampers, filling pipes with long-radius bend and cyclone. Outlet 0.3 x 0.3m. Delivered unassembled or assembled on site.

MAFA Indoor modular silo – with 45 degree cone.

The indoor modular silo is available in the dimensions 1.5×1.5 m, 2.05×2.05 m, 2.55×2.55 m and 3.0×3.0 m. (1.2 m3 – 83.0 m3). Made of galvanized steel plate. The silo is supplied with a lid, blower pipe, venting through a spring-loaded hatch and a dust filter. Delivered unassembled or assembled on site.

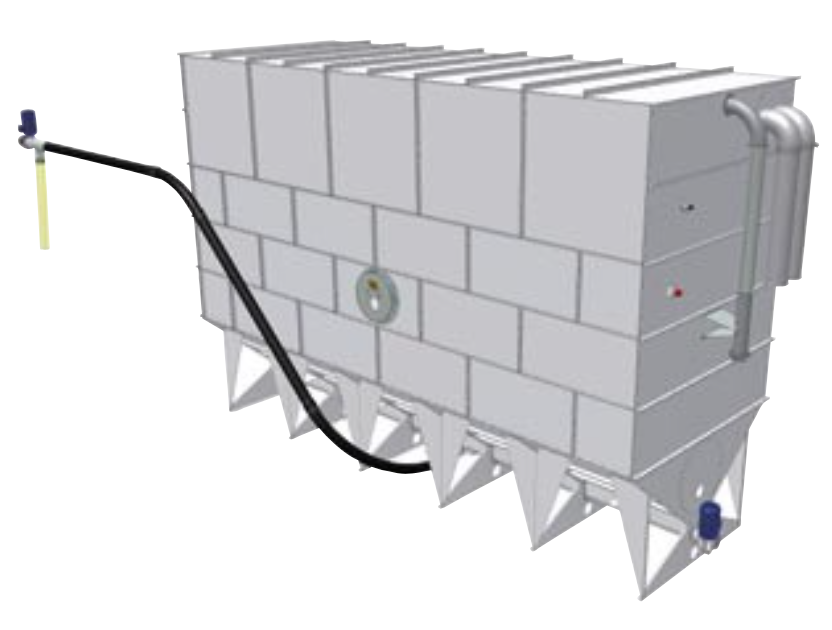

MAFA Indoor Rectangular Modular Silo

The indoor modular silo is available in the dimensions 1.3×2.55 m, 1.55×2.05 m, 2.05×3.0 m and 2.55×3.0 m. (3.6 m3 – 41.3 m3). Made of galvanized steel plate. The silo is supplied with a lid, blower pipe, venting through a spring-loaded hatch and a dust filter. Delivered unassembled or assembled on site.

Examples of Mafa's system solutions for fuel pellet plants

We have developed a number of system solutions to show how to adapt a MAFA fuel pellet plant to the conditions and to the existing environment. Whether you choose transport auger or vacuum transport, with or without intermediate storage, you get a flexible, reliable and easy-to-maintain system. However, the choice of system solution depends on the brand of the burner. The system solutions can be of great help to those who want to develop a cost level or a guide price (see price list on our website) for budget quotations or for preparatory design.

System Solution A

A suitable silo for plants around 50-100 kW is a MAFA Unik Small UNS 12 (12 m) silo, here with a seven-metre long flex auger from a 37° auger box. The silo is placed on a foundation outside the boiler room and a Maflex screw screws the pellets into the pellet burner/boiler. Available painted. Where there is space and opportunity, a round silo should always be used.

System Solution B

Suitable silo for plants around 100-300 kW is a MAFA Unique UN 27 (27 m3) silo, here with a seven-meter long flex auger from a 37° auger box. The silo is placed on a foundation outside the boiler room and a Maflex screw screws the pellets into the pellet burner/boiler. Available painted. Where there is space and opportunity, a round silo should always be used.

Systeml Solution C

A suitable silo for plants around 1.0-1.5 MW is a MAFA XB 189 (189 m3) silo, here with a four-meter 4 inch screw from a 15° – 45° auger box. The silo is placed on a foundation outside the boiler room. Where there is space and opportunity, a round silo should always be used.

System Solution D

A suitable silo for plants around 500-750 kW is a MAFA BIB 85 (85 m3) silo, here with a four-metre 4-inch auger fed from an adjustable auger box between 15-45°. The silo is placed on a foundation outside the boiler room. Can be clad at the bottom and/or painted. Where there is space and opportunity, a round silo should always be used.

System Solution E

Suitable silo for plants around 100-300 kW is a MAFA Outdoor Modular Silo (28 m3) silo with a seven-metre long flex auger from a 37° auger box. In some environments, a square silo is more suitable. Can be upholstered at the bottom and painted.

System Solution F

A suitable silo for plants around 300-500 kW is a MAFA BIB 40 (40 m) silo. Here with a five-metre-long flex auger from a 0° auger box. Suitable combination when the boiler room is in the basement. The silo is placed on a foundation outside the boiler room and the Maflex auger the pellets into the pellet burner/boiler. Can be clad at the bottom and/or painted. Where there is space and opportunity, a round silo should always be used.

System Solution H

The best option for installations around 100-300 kW, when it is impossible to place a high silo outdoors, is a Succé BSM 536 (25 m3). Here with a five-metre-long Maflex auger from the middle socket. Success can also be placed outdoors. It can be painted.

Outlet options for system solutions

Sometimes it can be an advantage to do the installation with an intermediate storage before the pellets are fed into the burner.

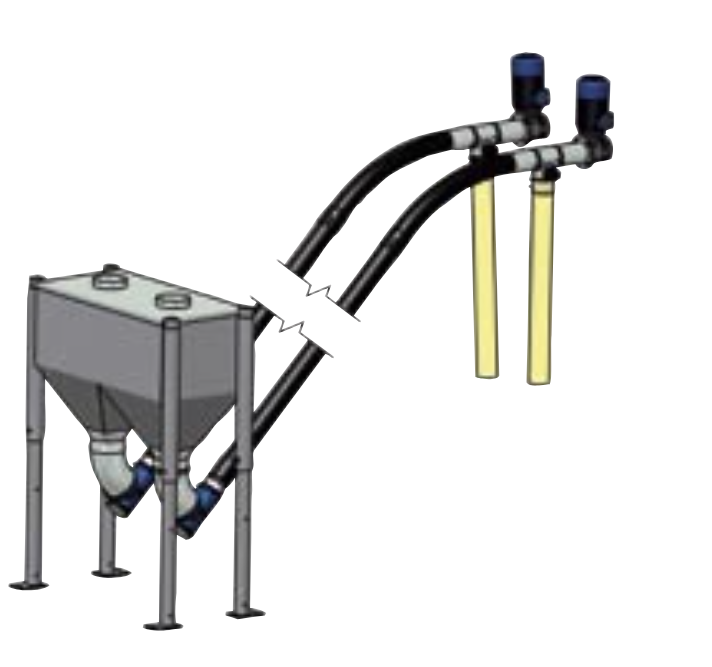

MAFA intermediate storage Special for particularly large quantities of pellets, here with double Maflex bendable transport augers

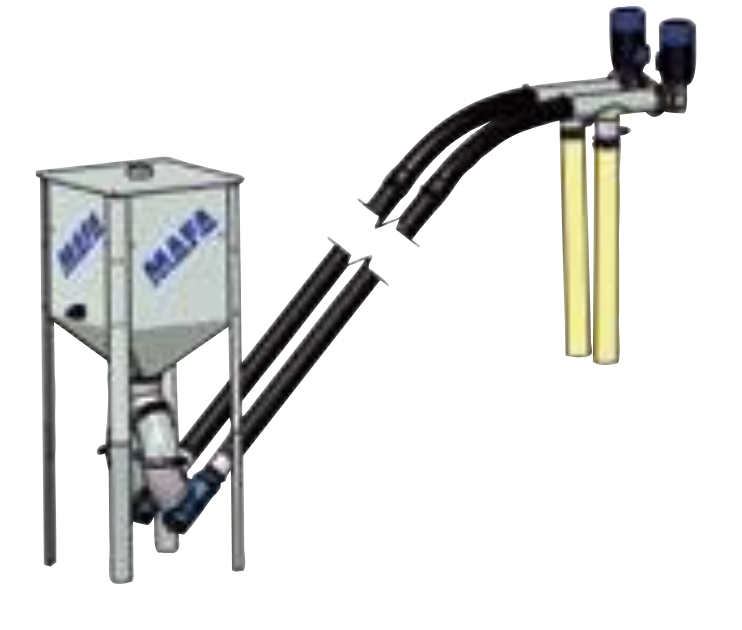

MAFA Intermediate Storage Mini with Dual Maflex Bendable Transport Augers

MAFA mid-storage midi with Maflex bendable transport augers