Tips for smaller pellet storage facilities

Size of the silo?

For a regular home burner, you usually choose a silo that holds at least 3 tons of pellets. This is to be able to get a whole bullet from the car.

Our house silo holds 5.7m³ which corresponds to a little over 3 tons.

It is also available in other sizes, both smaller and larger.

Things to consider when placing indoors

The room should have a ventilation of at least 4 dm².

The ceiling height in the room should be about 10 cm higher than the silo, this applies partly to the assembly and that the roof fabric rises when filling.

How is the silo placed in relation to the burner? Is screw solution possible?

Often the inlet pipe is pulled out through the wall to facilitate filling.

Things to consider when placing outdoors

It is important that the silo is level on a foundation or slabs under each leg. The foundation or slabs must be placed on a non-frost-heaving material.

The silo should be placed in such a way that it facilitates filling as much as possible.

Intermediate storage or auger directly to burner?

The burner models that have their own small internal storage are excellent to feed directly to. When it comes to burner models where the pellets fall directly into the burner cup, an intermediate storage is usually used, from where the burner’s own metering screw is used. Sensors are placed in the intermediate storage and an electrical control with a time function so that refilling is done completely automatically.

The reason why you use intermediate storage for some models is because they are so sensitive and since the feed from a bulk storage can be a little “jerky”, it is best with intermediate storage.

Vacuum conveying?

For long distances or difficult screwdriving (maybe a doorpost in the way?) you can advantageously use vacuum conveying. Of course, it can be used anyway, but since the price is a little higher compared to screws, screws are usually used for “simple” solutions.

When driving with vacuum conveying, an intermediate storage unit is always used.

Transport the material via auger

As few bends as possible, max 3 45gr or 2 90gr.

Avoid S-bending on the auger. At least 1m straight pipe in between if it has to be bent like an S.

Max slope of the auger= 45 gr.

Maximum length about 10-12 meters depending on the speed of the auger.

The radius of the bends is about 1 meter.

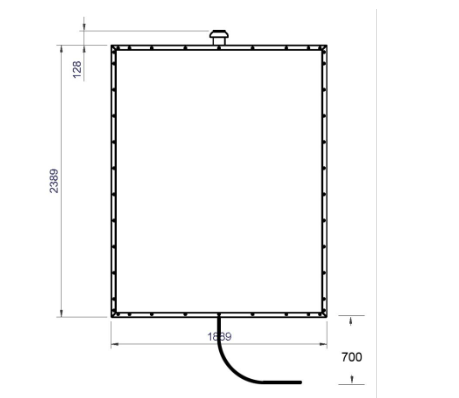

The house silo with 90gr bend. Keep in mind that the bend builds about 70cm outside the silo.

Possible solutions to pellet storage problems?

If longer augers than 10-12 meters are needed?

In some cases, dual operation can be used.

You can use 2 augers in a row, auger 1 hands over to auger 2.

Up to 50kW you can use vacuum conveying, MaVac.

The silo is located at ground level and the burner is in the basement?

Use 2 augers. The first pulls the pellets out of the silo and releases the pellets through a drop pipe to the second auger. Use different speeds on the engines, with the highest speed closest to the burner.

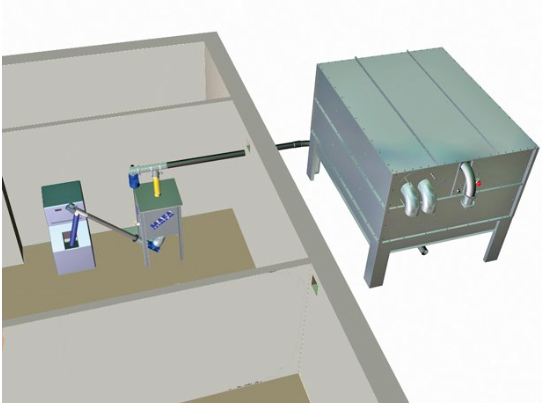

Villa Outdoor to an intermediate storage room type MAFA Mini

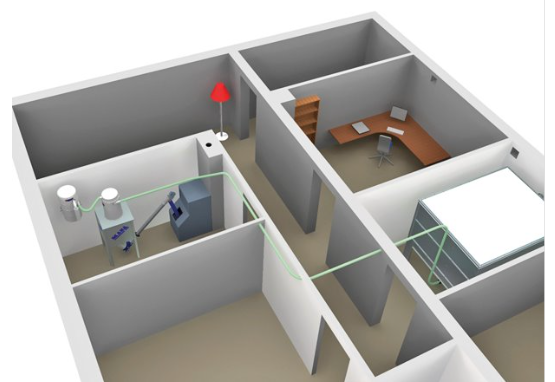

Villa Indoor with screw directly to burner

Villa Indoor with MaVac Vacuum Transport to MAFA Mini.