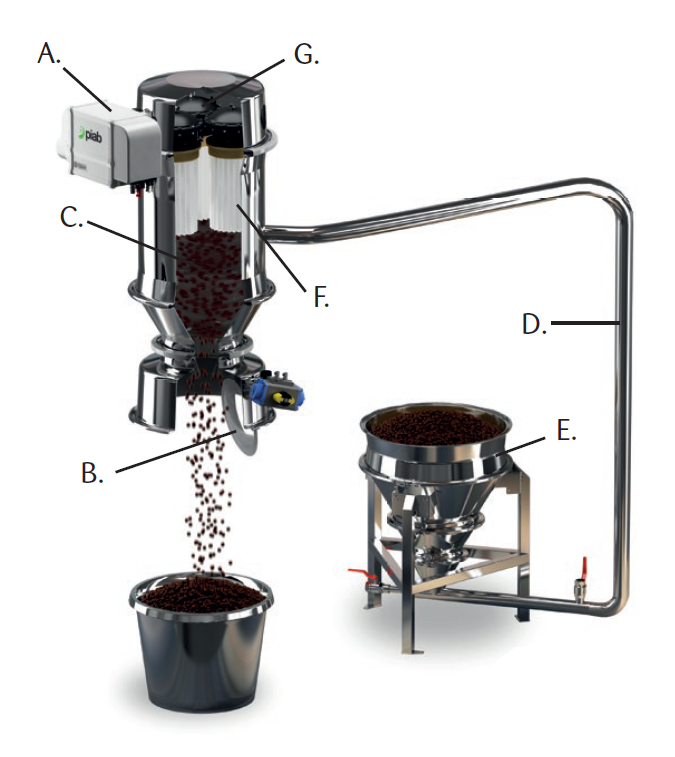

Vacuum conveying of powders

1. Vacuum is created by electromechanical pump (A)

The pump can be controlled automatically.

2. The bottom valve (B) closes and a negative pressure (vacuum)

created in the material container (C) and in the transport line (D).

3. From the dispatch station (E), the material is transported through

the transport line to the material container.

4. The filter (F) prevents dust and fine particles from entering pump and out into the surroundings.

5. During the material transport process, the air shock tanks (G) are filled

with compressed air.

6. At the preset time, the pump and material transport will be shut down

off and and the bottom valve (B) opens. Container

depleted of material at the same time as the air shock is activated and

The compressed air cleans the filter from dust and fine particles.

7. When the pump starts again, the process is repeated and a new one

Cycle starts. Suction and emptying times are normally controlled by

pneumatic or electrical control systems.

Feel free to contact us for more information and solution discussion.